What Are Prestressed Steel Strands?

2025-05-24

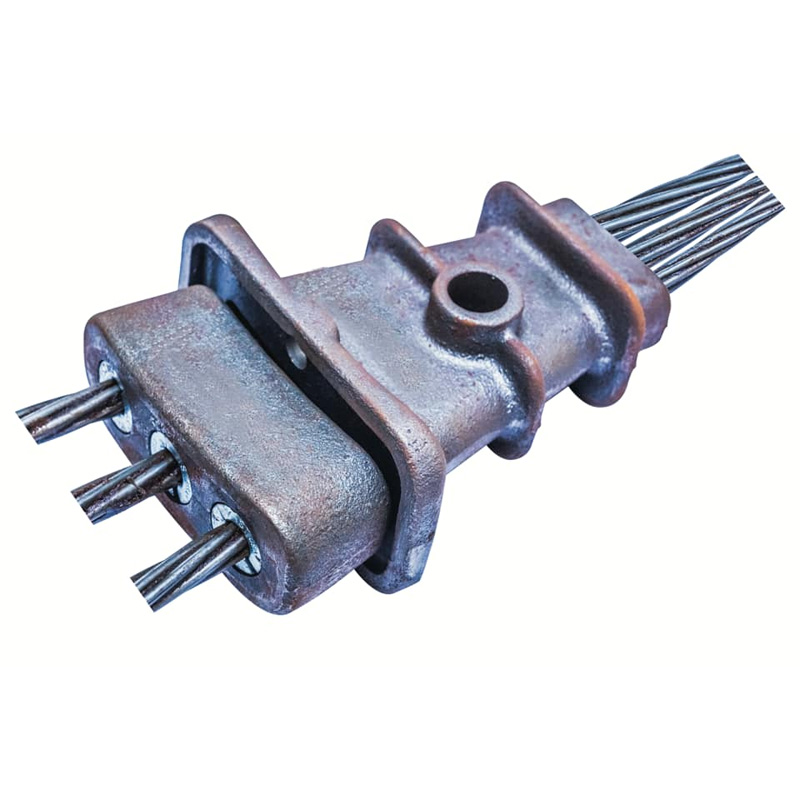

Prestressed steel strands are high-strength steel wires twisted together to form a cable or strand, commonly used in the construction of prestressed concrete structures. They typically consist of 7 wires — one central wire surrounded by six helical wires — and are either uncoated or galvanized, low-relaxation or normal-relaxation, depending on the application.

Prestressed steel strands are high-strength steel wires twisted together to form a cable or strand, commonly used in the construction of prestressed concrete structures. They typically consist of 7 wires — one central wire surrounded by six helical wires — and are either uncoated or galvanized, low-relaxation or normal-relaxation, depending on the application.

Principle of Prestressing

The basic concept behind prestressing is to pre-load the concrete structure using tensioned steel strands before it is subjected to external loads. This method introduces a compressive force into the concrete, which helps counteract the tensile forces that occur under service loads.

How It Works:

Tensioning the Strands: Steel strands are stretched (tensioned) using hydraulic jacks.

Anchoring to Concrete: The stretched strands are anchored at both ends of a concrete element.

Transferring Stress: Once the concrete has reached sufficient strength, the tension in the strands is gradually released, transferring the force to the concrete.

Result: The concrete is compressed, improving its ability to resist tension, cracking, and deflection.

Key Properties

High Tensile Strength: Typically around 1860 MPa (or more).

Excellent Bonding with Concrete (especially when indented or with a rough surface).

Low Relaxation: Maintains tension over long periods.

Durability: Can be galvanized or epoxy-coated for corrosion protection.

Applications of Prestressed Steel Strands

Prestressed steel strands are essential in various fields of civil engineering and infrastructure. Common applications include:

1.Bridge Construction

Prestressed beams and girders

Box girders and cable-stayed bridges

Post-tensioned deck slabs

2.Buildings

Long-span floor slabs

Parking garages

High-rise buildings requiring seismic resistance

3.Railways and High-Speed Rail

Railway sleepers (ties)

Long viaducts and elevated tracks

4.Energy Sector

Wind turbine foundations

Nuclear containment structures

LNG storage tanks

5.Marine and Offshore

Wharf structures

Offshore platforms

Coastal retaining walls

Advantages of Using Prestressed Steel Strands

Improved Structural Efficiency: Reduces material use while enhancing load-bearing capacity.

Longer Spans: Enables construction of long spans without intermediate supports.

Enhanced Durability: Cracking is minimized, which improves lifespan and reduces maintenance.

Lightweight Design: Allows thinner and lighter concrete sections.

Cost Savings: Reduces construction time and overall material costs in large-scale projects.